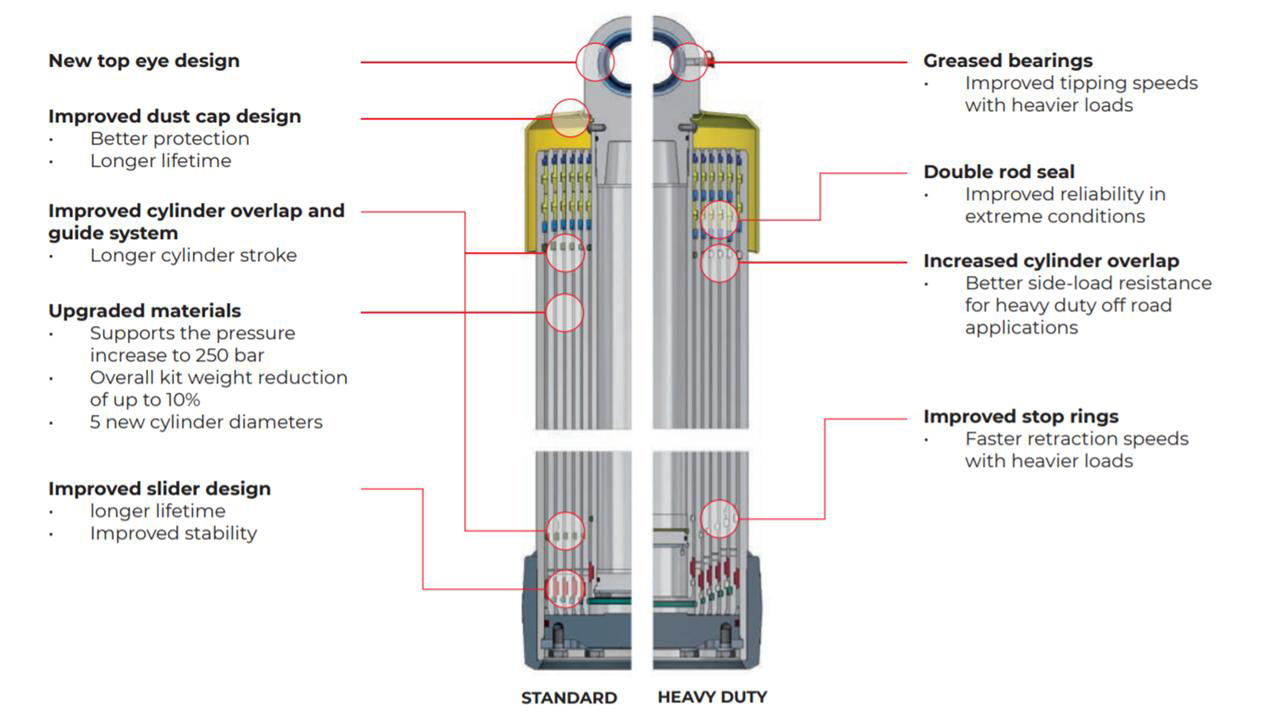

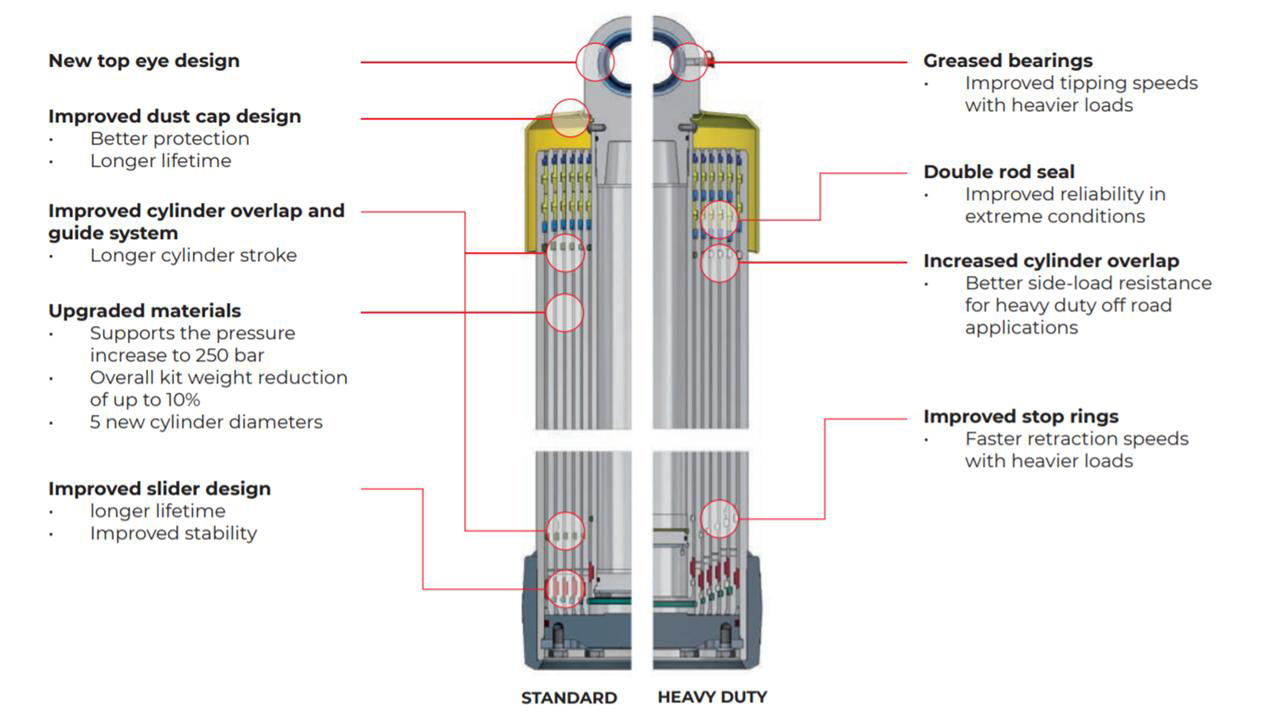

Front End Cylinders

Our Alpha Series is lighter, faster, safer and more efficient. It is the latest and fifth generation of front end tipping solutions. A complete system - cylinder, brackets and wet kit - it’s designed to deliver higher efficiency and safer operation at lower cost for applications such as mining, transportation and construction. Read more.

FE

The Hyva FE cylinder is lightweight, strong, stable and maintenance free and typically used when the headboard is slanted (angled). The tipping capacity for FE cylinders ranges up to over 100 tons. Our trunnion type FE tipping cylinders bring reduced weight and faster tipping to on-road rigids and (semi-) trailers.

FC telescopic front-end cylinders are primarily designed for straight headboard types with a capacity range of over 100 tons tipping weight. Our trunnion type FC cylinder is lightweight, strong, maintenance free and offers the most added stability to the tipper. The Hyva FC tipping cylinders have earned reputation for their reliability and value for money over many years.

For more Information Download PDF

Wet Kit

With knock-off and control options, cylinder-mounted tipping valves and filter options, Hyva Wet Kits feature gear pumps able to operate up to 250 bar. They’re highly flexible, too, as all elements can be installed on a modular basis - though maximum benefit is gained from use of the whole system.

Lower Dead Weight = Higher payload

Faster tipping and lowering = Shorter cycle time

Safer and more reliable = Reduced downtime

Most efficient = Productive & profitable

Cost effective = Can reduce operating costs

Longer service intervals = increased operating time

Lower oil & fuel consumption = Environmental friendly

Each of the hydraulic systems for tipping consists of a number

of vital components, selected and assembled according

to the requirements of each specific application:

- Operating pressure (cylinder, valve, pump)

- Flow (pump, valve, hoses, adapters)

- Cylinder capacity (oil tank volume)

- Type of vehicle

- Type of gear box

- Type of PTO

- Torque of PTO

- Direction of PTO rotation

- Tipping time

- The position on the vehicle for individual elements, the system efficiency

- Control system and other extra functions

Explanation Of Rigid Wetkit Parts

01

CYLINDER

Higher operating pressure

faster, shorter cycle time

02

TIPPING VALVE

Cylinder mounted optimised

control

safer

03

COVER & LIFTING BRACKET

Forged steel and cast iron

Different bearing options available

lower weight

04

KNOCK OFF

Precise actuation

Robust design Easy

installation

safer

05

CHASSIS BRACKET

Cast iron

Different bearing options available

lower weight

06

CRADLE

Standardised kits

Improved hose management

easy installation & mounting

07

PUMP

High pressure

Durability

faster

08

TANK

Reinforced body

Straps mounted

Oil volume balanced to cylinder

stronger, lighter & more reliable

09

FILTERS

Optimised oil and air flow

Standard and optional heavy duty

version

new design

HYVA Smart

Intelligent tipping

We believe in empowering drivers through technology, in making tipping efficient, safe and easy. Hyva Smart monitors important safety aspects and intervenes when needed, with faster-than-human reflexes. Features such as empty body indication and easy lower help you save valuable time and will provide more comfort and control during your work.

Hyva Smart Fleet Management Solution

is designed to increase fleet efficiency

and productivity.

The new, sensor-based monitoring system

adds intelligence to tipping vehicles.

It provides the advice and assistance

which helps make better decisions,

improving safety and efficiency before

and during the tipping operation.

The system is compatible with Hyva front

end cylinders – Flash (retro-fit) and Alpha

(retro-fit or new) – in Mining, Construction

and Transport applications. It is available

for both rigid trucks and tractor-trailers.

Supported on Android operating system,

it is available in multiple languages, and,

in both Imperial and Metric calibration.

Additional analogue sensors can be

added to the system and their outputs

will display in the Smart phone App, e.g.

proximity sensors for sheeting system or

rear door position.

Benefits

Driver awareness of (tipping) safety, especially under variable operating conditions.

Reduced damages and liability due to unsafe operation.

Improved performance

due to partial automation

of customer

workflow, and insights

into driver behaviour.

Reduced manual trip

administration.

Optimized uptime due

to planning of maintenance

based on actual

use.

Expandable product

platform to meet

market (segment)

specific needs.

Features

For The Fleet Owner

- Tipping truck location and history routes

- Tipping truck trip data (for example: how much has been unloaded and where was it

unloaded)

- Fleet analysis pages (for example: overview with bar graphs to compare different trucks

with each other)

- Management reports (Showing performance and maintenance information in table

format)

For The Driver

- Warning for dangerous side load angle (2 steps: first alert and then danger warning)

and warning for overload

- Payload indication, body empty indication and tipping summary

- Statistics with amount of load and tipping cycles per day and total lifetime

- Maintenance information and warnings (air filter replacement, return filter replacement, cylinder oil change, bush replacement and bush greasing)

- Designed for day and night, 24/7